How 3D Printing is Revolutionizing Toy Design

In recent years, 3D printing has emerged as a groundbreaking technology that is reshaping industries across the globe. One of the most exciting areas of transformation is within the toy industry, where 3D printing is revolutionizing the way toys are designed, produced, and enjoyed by children and collectors alike. In this blog post, we’ll explore how 3D printing is making waves in toy design, unlocking limitless creativity and personalization.

Table of Contents

1. Introduction to 3D Printing in Toy Design

2. The Benefits of 3D Printing for Toy Manufacturers

3. Customization: A New Frontier in Toy Design

4. Sustainability and Cost Efficiency

5. Challenges and Considerations

6. The Future of Toy Design with 3D Printing

7. Conclusion

8. FAQs

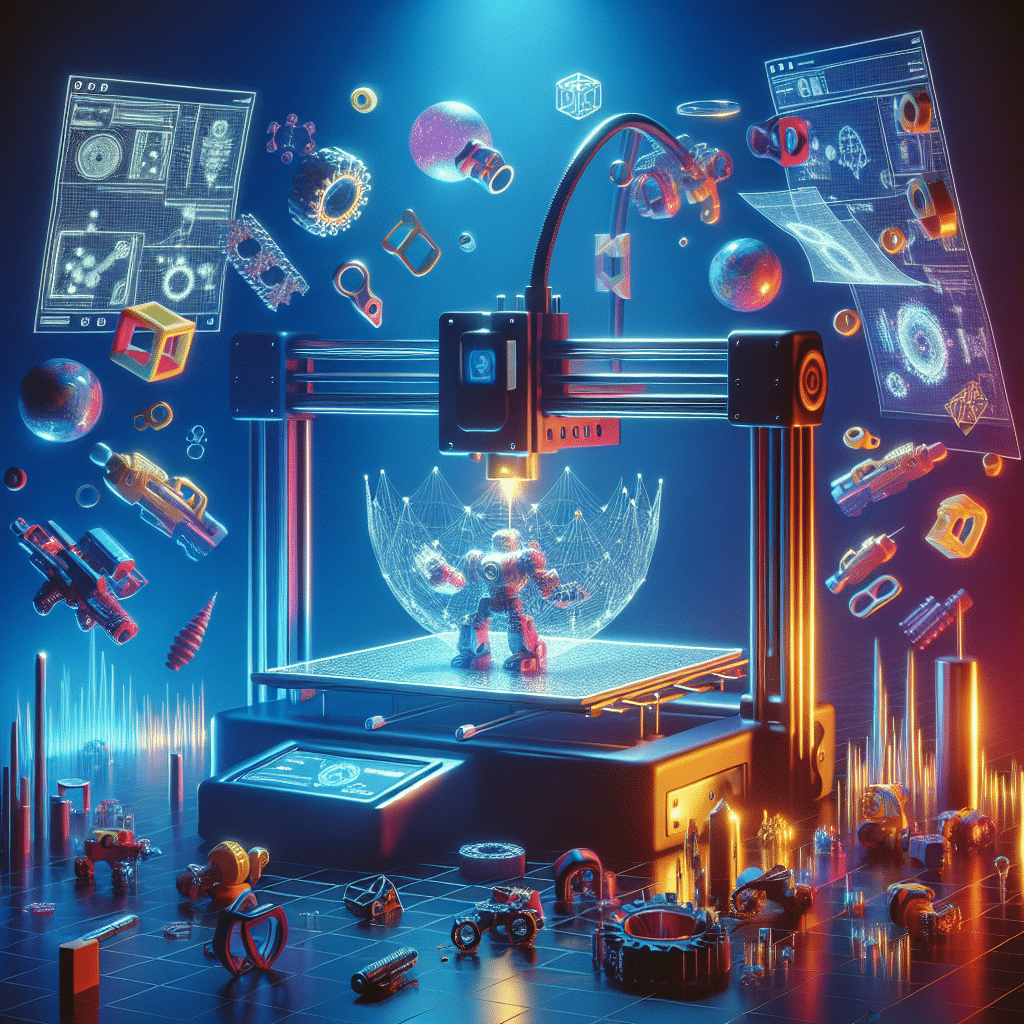

Introduction to 3D Printing in Toy Design

The world of toy design has always been driven by creativity and innovation. With the advent of 3D printing, designers now have a powerful tool to bring their wildest ideas to life. 3D printing, also known as additive manufacturing, involves creating objects layer by layer from a digital file. This technology allows for the production of complex shapes and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods.

The Benefits of 3D Printing for Toy Manufacturers

One of the primary advantages of 3D printing in toy design is the speed and efficiency it offers. Traditional toy manufacturing processes can be time-consuming and costly, often requiring the creation of molds and extensive prototyping. With 3D printing, prototypes can be produced quickly and at a fraction of the cost, enabling faster iteration and refinement of designs.

Moreover, 3D printing allows toy manufacturers to produce small batches of toys without the need for large-scale production runs. This flexibility reduces waste and allows for more experimentation with new designs and concepts.

Customization: A New Frontier in Toy Design

Imagine being able to design your own action figure or customize a doll to look like your favorite character. With 3D printing, this level of personalization is now possible. Toy companies can offer a wide range of customization options, allowing consumers to tweak colors, features, and even the size of their toys. This not only enhances the play experience but also fosters a deeper emotional connection between the toy and its owner.

Personalization is a powerful trend in the toy industry, and 3D printing is at the forefront of this movement, enabling unique, one-of-a-kind toys that cater to individual preferences.

Sustainability and Cost Efficiency

As environmental concerns continue to grow, sustainability has become a key consideration for many industries, including toys. 3D printing offers a more sustainable approach to toy manufacturing by minimizing waste and reducing the carbon footprint. Traditional manufacturing methods often involve excess material and energy consumption, whereas 3D printing uses only the necessary amount of material to create each toy.

Furthermore, 3D printing can be more cost-effective in the long run. The reduction in material waste and the ability to produce on-demand means lower storage costs and less financial risk for toy companies.

Challenges and Considerations

While 3D printing presents numerous advantages, there are still challenges to overcome. The initial setup costs for 3D printing technology can be high, and the speed of production may not yet match that of traditional mass production methods. Additionally, the quality and durability of 3D-printed toys need to be carefully monitored to ensure they meet safety standards.

Despite these challenges, continuous advancements in 3D printing technology are addressing these issues and paving the way for broader adoption in the toy industry.

The Future of Toy Design with 3D Printing

The future of toy design is undoubtedly exciting with the integration of 3D printing. As the technology matures, we can expect even more innovation and creativity. The potential for collaboration between designers, consumers, and even children themselves opens up a world of possibilities for interactive and educational play experiences.

With 3D printing, the boundary between imagination and reality blurs, empowering both creators and consumers to shape the toys of tomorrow.

Conclusion

3D printing is revolutionizing toy design by offering unprecedented levels of creativity, customization, and sustainability. As the technology continues to evolve, it will undoubtedly play a pivotal role in shaping the future of the toy industry. Whether you’re a toy enthusiast, a parent, or a designer, 3D printing holds endless possibilities for bringing imaginative ideas to life and enhancing the way we play and connect with toys.

FAQs

Q: What is 3D printing?

A: 3D printing is a process of creating three-dimensional objects from a digital file by layering materials.

Q: How does 3D printing benefit toy design?

A: It offers speed, cost efficiency, customization, and reduces waste, allowing for innovative and personalized toy designs.

Q: Are 3D-printed toys safe for children?

A: Yes, but manufacturers must ensure that the materials and designs meet safety standards and regulations.

Q: Can I design my own toy with 3D printing?

A: Absolutely! Many companies offer customization services where you can design and personalize your own toys.

Q: What is the future of 3D printing in toys?

A: The future is bright, with more innovation, collaboration, and interactive play experiences on the horizon thanks to 3D printing.

🎲✨ Embrace the future of play with 3D printing! 🌟🏗️